DC/DC Converters

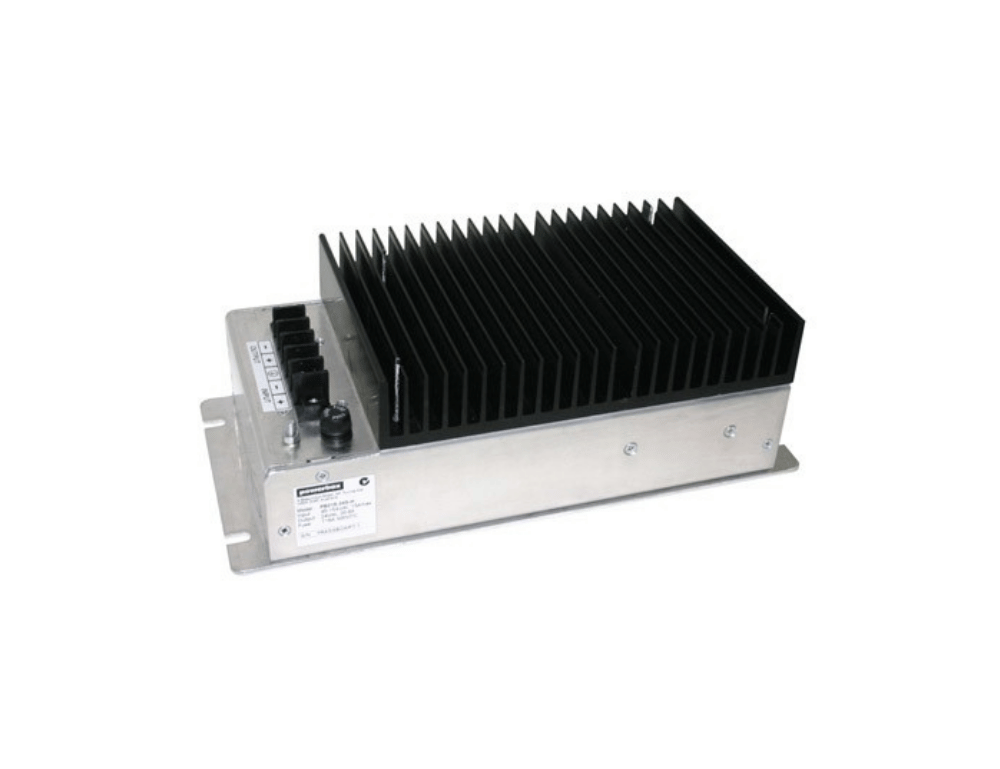

Powerbox PB315 Headlight Controller - Railway

The Powerbox PB315 Headlight Controller is a robust 626W solution designed to manage locomotive headlights with precision and reliability. Built to control two GE350PAR56/SP-75 sealed beam headlights, it ensures optimal performance under the harsh conditions of rolling stock operations.

Read MoreFeatures

- 626W

- 72V & 110VDC Inputs

- Rail DC / DC Converter

- Controls Two Locomotive Sealed Beam Headlights

- High Temp Operation

- Ruggedised Shock and Vibration

Specifications

Downloads

| INPUT | |

|---|---|

| Input voltage | 72Vin (45-101Vdc) or 110Vin (66-154Vdc) |

| Input current | 16A at 72Vin, 12A at 110Vin |

| Inrush Current | 16A at 72Vin, 25A at 110Vin |

| DC ripple factor | 15% |

| OUTPUT | |

|---|---|

| Voltage | High beam = 68Vdc, Low beam 72Vin = 32Vdc, Low beam 110Vin = 25Vdc |

| Current | High beam = 9.2A, Low beam 72Vin = 6.6A, Low Low beam 110Vin = 6.0A |

| Continuous power | 626W max |

| Ripple voltage | 200mV p-p |

| Line regulation | 0.5% at full load |

| Load regulation | 1.5% from 0 to full load |

| OPERATION | |

|---|---|

| Efficiency | 93% at full load typical |

| Power dissipated | 50W at full load typical |

| Isolation | Input to Chassis - 2400Vdc Input to Output – 3800Vdc Output to Chassis – 750Vdc |

| Temperature | Up to 50C ambient at full load. Derate linearly from 50C full load to 80C zero load |

| Cooling | Natural convection. No additional cold plate or heatsinking required |

| PROTECTION | |

|---|---|

| Input reverse polarity | Indefinite. Series diode on input |

| High input ripple | Indefinite. Series diode on input |

| Input overvoltage | Approx 108Vdc for 72Vin, 168Vdc for 110Vin, Auto Recovery |

| Output overcurrent | 115% of nominal. Auto recovery |

| Output short circuit | Indefinite. Auto recovery |

| Output overvoltage | 125% nominal, Input cycled off & on to reset |

| Over temperature | 105C internal temperature. Auto restart |

| Pollution protection | PD3 as per IEC60077-1 |

| Ingress protection | IP40 as per AS1939 |

| Rated inpulse withstand volts | Input 2.5kV, Output 0.8kV as per IEC60077-1 |

| CONTROLS AND ALARMS | |

|---|---|

| High/low beam | High beam for control signal < 20Vdc Low beam for 20Vdc < control signal < 154Vdc |

| On/Off (for 110Vin only) | Unit disabled for control signal < 20Vdc Unit enabled for 20V < control signal < 154Vdc |

| Headlight Fail | Volt free contact closes under failure conditions |

| MECHANICAL | |

|---|---|

| Enclosure | Chassis Mount Aluminium |

| Dimensions | 322L x 150W x 102H including heatsink |

| Weight | 4.0 kg |

| Terminations | Screw Terminals as standard. Other terminals such as Cage Clamp, Fastons available on request |

| STANDARDS | |

|---|---|

| Safety | Meets IEC60077-1, AS/NZS 60950-2000 |

| EMC / EMI | Meets EN50121-3-2:2000 and EN50155 |

| Electrical service conditions | Meets EN50155 |

| INPUT | |

|---|---|

| Input voltage | 72Vin (45-101Vdc) or 110Vin (66-154Vdc) |

| Input current | 16A at 72Vin, 12A at 110Vin |

| Inrush Current | 16A at 72Vin, 25A at 110Vin |

| DC ripple factor | 15% |

| OUTPUT | |

|---|---|

| Voltage | High beam = 68Vdc, Low beam 72Vin = 32Vdc, Low beam 110Vin = 25Vdc |

| Current | High beam = 9.2A, Low beam 72Vin = 6.6A, Low Low beam 110Vin = 6.0A |

| Continuous power | 626W max |

| Ripple voltage | 200mV p-p |

| Line regulation | 0.5% at full load |

| Load regulation | 1.5% from 0 to full load |

| OPERATION | |

|---|---|

| Efficiency | 93% at full load typical |

| Power dissipated | 50W at full load typical |

| Isolation | Input to Chassis - 2400Vdc Input to Output – 3800Vdc Output to Chassis – 750Vdc |

| Temperature | Up to 50C ambient at full load. Derate linearly from 50C full load to 80C zero load |

| Cooling | Natural convection. No additional cold plate or heatsinking required |

| PROTECTION | |

|---|---|

| Input reverse polarity | Indefinite. Series diode on input |

| High input ripple | Indefinite. Series diode on input |

| Input overvoltage | Approx 108Vdc for 72Vin, 168Vdc for 110Vin, Auto Recovery |

| Output overcurrent | 115% of nominal. Auto recovery |

| Output short circuit | Indefinite. Auto recovery |

| Output overvoltage | 125% nominal, Input cycled off & on to reset |

| Over temperature | 105C internal temperature. Auto restart |

| Pollution protection | PD3 as per IEC60077-1 |

| Ingress protection | IP40 as per AS1939 |

| Rated inpulse withstand volts | Input 2.5kV, Output 0.8kV as per IEC60077-1 |

| CONTROLS AND ALARMS | |

|---|---|

| High/low beam | High beam for control signal < 20Vdc Low beam for 20Vdc < control signal < 154Vdc |

| On/Off (for 110Vin only) | Unit disabled for control signal < 20Vdc Unit enabled for 20V < control signal < 154Vdc |

| Headlight Fail | Volt free contact closes under failure conditions |

| MECHANICAL | |

|---|---|

| Enclosure | Chassis Mount Aluminium |

| Dimensions | 322L x 150W x 102H including heatsink |

| Weight | 4.0 kg |

| Terminations | Screw Terminals as standard. Other terminals such as Cage Clamp, Fastons available on request |

| STANDARDS | |

|---|---|

| Safety | Meets IEC60077-1, AS/NZS 60950-2000 |

| EMC / EMI | Meets EN50121-3-2:2000 and EN50155 |

| Electrical service conditions | Meets EN50155 |

Find the Right Model

| Model Number | Input Voltage (Vdc) | Output Voltage (Vdc) | Output Current (A) | ||

|---|---|---|---|---|---|

|

PB315-72-68F-HE | 72Vdc: 45...101Vdc | High beam = 68Vdc Low beam 72Vin = 32Vdc | High Beam = 9.2A Low Beam 72Vin = 6.6A | |

|

PB315-110-68F-HB | 110Vdc: 66...154Vdc | High Beam = 68Vdc Low Beam 110Vin = 25Vdc | High Beam = 9.2A Low Beam 110Vin = 6.0A |

Need help finding the right product model?